Industrial unit heaters are vital for maintaining optimal temperatures in diverse settings like manufacturing facilities and warehouses. These specialized solutions offer focused radiant warmth with robust construction, suitable for demanding commercial applications. Types include gas-fired, electric, suspended, and forced air heating systems, each with specific BTU ratings for customizable temperature control. Infrared technology enhances efficiency by directly warming surfaces, minimizing energy wastage. Proper selection is key, considering environment, space, and temperature requirements to ensure optimal heating in industrial settings.

Infrared industrial unit heaters are transforming how we heat large spaces, offering a targeted and efficient approach to temperature control. This article delves into the world of these innovative heating solutions, exploring their role in industries from manufacturing to logistics. We’ll uncover the science behind infrared radiant warmth, its numerous advantages, and diverse applications. Discover why choosing the right industrial unit heater is crucial for optimizing your space and enhancing productivity.

- Understanding Industrial Unit Heaters: Their Role and Benefits

- The Science Behind Infrared Radiant Warmth

- Advantages of Infrared Industrial Unit Heaters

- Applications: Where are They Used?

- Choosing the Right Infrared Heater for Your Industrial Needs

Understanding Industrial Unit Heaters: Their Role and Benefits

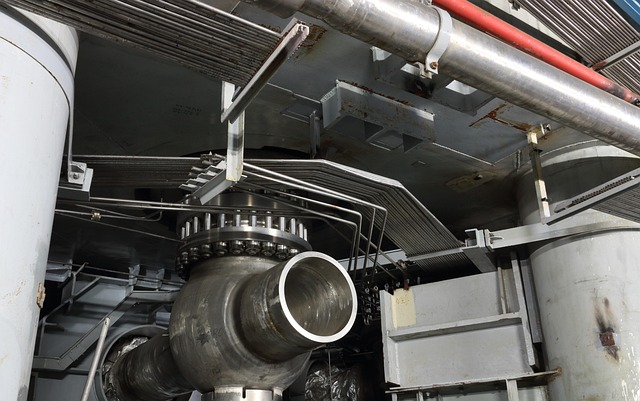

Industrial unit heaters play a pivotal role in maintaining optimal temperatures across various industrial settings, from manufacturing facilities to vast warehouses. These specialized heating solutions are designed to efficiently deliver focused radiant warmth, ensuring a controlled and precise environment. Their robust construction, typically featuring heavy-duty materials, makes them well-suited for demanding commercial heating applications.

The benefits of employing industrial unit heaters are numerous. Gas-fired heaters, for instance, offer quick response times and cost-effective operation, while electric unit heaters provide clean, quiet, and energy-efficient warmth. Suspended heaters, strategically positioned, can effectively heat large areas, making them ideal for manufacturing facilities requiring consistent temperatures. Moreover, forced air heating systems enhance circulation, ensuring every corner of a warehouse or industrial space is comfortable and safe, catering to the diverse needs of various industrial applications. Each unit comes with specific BTU ratings, allowing businesses to select the perfect fit based on their space and temperature requirements.

The Science Behind Infrared Radiant Warmth

Infrared radiant warmth is a scientific phenomenon that has been harnessed for use in industrial settings through industrial unit heaters. These heaters work by converting electrical energy or fuel into thermal radiation, which is then emitted as heat towards targeted objects or spaces. Unlike forced air heating or gas fired heaters, which rely on convection currents to distribute heat, infrared heaters directly warm the surface of an object, making them highly efficient in heavy duty construction and industrial applications like warehouse heating and manufacturing facilities.

The process begins when energy sources such as electric current or combustible gases pass through a specialized emitter, causing electrons to become excited. These energized electrons then release their excess energy in the form of infrared radiation, which travels through space until it encounters a cooler surface, where its energy is absorbed, warming that surface and any surrounding objects. This direct heating method ensures that heat is delivered precisely where needed, making industrial unit heaters particularly effective for commercial heating in various industrial applications. BTU ratings vary based on model and power source, catering to different warehouse heating needs and ensuring optimal performance in specific manufacturing facilities.

Advantages of Infrared Industrial Unit Heaters

Infrared industrial unit heaters offer several significant advantages in various industrial settings. One of their key benefits is the ability to deliver focused radiant warmth, ensuring efficient heating of specific areas within large warehouses or manufacturing facilities. Unlike traditional forced air heating methods, which can be less targeted and result in energy wastage, these heaters directly heat objects, making them ideal for heavy-duty construction sites and other industrial applications that demand precise temperature control.

Furthermore, both gas fired heaters and electric unit heaters equipped with infrared technology provide superior performance in terms of BTU ratings, ensuring quick and effective warming. The suspended design of many industrial unit heaters allows for easy installation and maintenance, making them a flexible solution for commercial heating needs. This versatility makes infrared industrial unit heaters an attractive option for businesses looking to optimize their energy usage and enhance productivity through efficient warehouse heating.

Applications: Where are They Used?

Infrared industrial unit heaters find their niche in a variety of demanding environments, particularly in warehouse heating and manufacturing facilities. Their ability to deliver focused radiant warmth makes them ideal for heavy duty construction sites where maintaining consistent temperatures is crucial for worker safety and productivity. These heaters come in various forms, including gas fired heaters, electric unit heaters, and even suspended heaters, each designed to suit specific needs.

For instance, forced air heating systems equipped with high BTU ratings are perfect for spacious industrial applications that require quick temperature regulation. In contrast, suspended heaters are versatile and can be easily positioned to target specific areas, making them suitable for both temporary and permanent installations. Regardless of the setup, these heaters ensure optimal commercial heating, contributing to a productive and comfortable work environment in even the harshest industrial applications.

Choosing the Right Infrared Heater for Your Industrial Needs

When selecting an infrared industrial unit heater for your specific needs, several factors come into play. Understanding the unique requirements of your warehouse heating or manufacturing facilities is essential. Different applications may demand various types of heaters; for instance, gas fired heaters offer efficient outdoor solutions, while electric unit heaters are ideal for controlled interior environments. Heavy-duty construction sites might benefit from suspended heaters, ensuring maximum coverage with minimal obstruction.

Consider the space you need to heat and the BTU ratings required to match your commercial heating demands. Forced air heating systems can be beneficial in large, open spaces, providing quick and even distribution of warmth. In contrast, radiant heaters, such as infrared models, excel at direct, focused heating, making them suitable for specific industrial applications where precise temperature control is crucial.

Infrared industrial unit heaters offer a powerful and efficient solution for heating large industrial spaces, providing focused radiant warmth that significantly enhances productivity. Their unique ability to directly heat objects and people makes them an indispensable tool in various industries. By understanding the science behind infrared technology and selecting the right heater for specific needs, businesses can optimize their operations and reap the benefits of this innovative heating method. Industrial unit heaters are a game-changer when it comes to maintaining optimal temperatures, ensuring a productive and comfortable work environment.